Iminyango namafasitela e-aluminium alloy amaphrofayili azophathwa phezulu. Izingxenye zefreyimu yomnyango nefasitela ezenziwe ngokuvala, ukubhoboza, ukugaya, ukuthepha, ukwenza amafasitela nezinye izindlela zokucubungula, bese kuhlanganiswe nezingxenye zokuxhuma, izingxenye zokuvala, nokuvula nokuvala i-hardware.

I-aluminium alloy system iminyango namafasitela ingahlukaniswa iminyango namafasitela eslayidayo, iminyango namafasitela e-casement, iminyango yesikrini namafasitela, ukuvulwa kwangaphakathi namafasitela aphikisayo, ama-shutter, amafasitela ahleliwe, amafasitela alengayo, njll ngokusho kwesakhiwo sabo kanye nezindlela zokuvula nokuvala. Ngokusho kokubukeka okuhlukile nokucwebezela, iminyango namafasitela e-aluminium alloy ingahlukaniswa ngemibala eminingi njengomhlophe, ompunga, onsundu, okusanhlamvu kwezinkuni, neminye imibala ekhethekile. Ngokusho kochungechunge oluhlukene lokukhiqiza (ngokusho kobubanzi besigaba somnyango kanye nephrofayili yefasitela), iminyango ye-aluminium alloy namafasitela ingahlukaniswa ngochungechunge lwe-38, uchungechunge lwama-42, uchungechunge lwama-52, uchungechunge lwama-54, uchungechunge lwama-60, uchungechunge lwama-65, uchungechunge lwama-70, uchungechunge lwe-120, njll.

1. Amandla

Amandla eminyango namafasitela wesistimu ye-aluminium alloy avezwa izinga lokucindezela komoya elisetshenziswa ngesikhathi sokuhlolwa kokucindezela komoya ocindezelwe ebhokisini lokucindezela, futhi iyunithi ingu-N/m2. Amandla we-aluminium alloy iminyango namafasitela ngokusebenza okujwayelekile angafinyelela ku-196l-2353 N/m2, futhi amandla amafasitela asebenza kahle kakhulu e-aluminium alloy angafinyelela ku-2353-2764 N/m2. Ukukhishwa okuphezulu okukalwa maphakathi nendawo ye-casement ngaphansi kwengcindezi engenhla kufanele kube ngaphansi kuka-1/70 wobude bonqenqema lwangaphakathi lohlaka lwewindi.

2. Ukucinana komoya

Iwindi le-aluminium ingxubevange lisegunjini lokuhlola ingcindezi, ukuze iwindi elingaphambili nangemuva lenze umehluko wengcindezi ongu-4.9 kuya ku-9.4 N/m2, futhi ivolumu yokungenisa umoya endaweni ye-m2 ngeh (m3) ikhombisa ukungangeni komoya kwewindi, futhi iyunithi ingu-m³/m²·h. Uma umehluko wengcindezi phakathi kwangaphambili nangemuva kwewindi lengxubevange ye-aluminium ngokusebenza okuvamile kungu-9.4N/m2, ukungangeni komoya kungafinyelela ngaphansi kuka-8m³/m²·h, futhi iwindi lengxubevange ye-aluminium elinomoya ophezulu lingafinyelela ngaphansi kuka-2 m³/m²·h. i

3. Ukuqina kwamanzi

Izicabha namafasitela esistimu akugumbi lokuhlola ingcindezi, futhi ingaphandle lefasitela lingaphansi kwengcindezi ye-sine wave enenkathi engu-2s. Ngesikhathi esifanayo, i-4L yemvula yokufakelwa idluliselwa efasiteleni ngesilinganiso se-4L nge-m2 ngomzuzu, futhi ukuhlolwa "komoya nemvula" kwenziwa imizuzu eyi-10 ngokuqhubekayo. Akufanele kube khona ukuvuza kwamanzi okubonakalayo ohlangothini lwangaphakathi. Ukungangeni kwamanzi kumelelwa ukucindezela okufanayo komfutho womoya oshaywayo osetshenziswa ngesikhathi sokuhlolwa. Iwindi le-aluminium alloy elisebenzayo elijwayelekile lingu-343N/m2, futhi iwindi elimelana nesishingishane elisebenza kakhulu lingafinyelela ku-490N/m2.

4. Ukuvala umsindo

Ukulahlekelwa kokudluliswa komsindo kwamafasitela e-aluminium alloy kuhlolwa elabhorethri ye-acoustic. Kungatholakala ukuthi lapho imvamisa yomsindo ifinyelela inani elithile, ukulahlekelwa komsindo wokudlulisa umsindo wefasitela le-aluminium alloy kuvame ukuba njalo. Ukusebenzisa le ndlela ukuze kunqunywe ijika lezinga lokusebenza kokufakwa komsindo, ukulahlekelwa komsindo wokudlulisa umsindo wamafasitela e-aluminium alloy anezidingo zokuvala umsindo kungafinyelela ku-25dB, okungukuthi, izinga lomsindo lingancishiswa ngo-25dB ngemva kokuba umsindo udlule efasiteleni le-aluminium alloy. Amafasitela e-aluminium alloy asebenza ngokufaka umsindo ophezulu, ijika lezinga lokulahlekelwa kokudluliswa komsindo lingu-30~45dB.

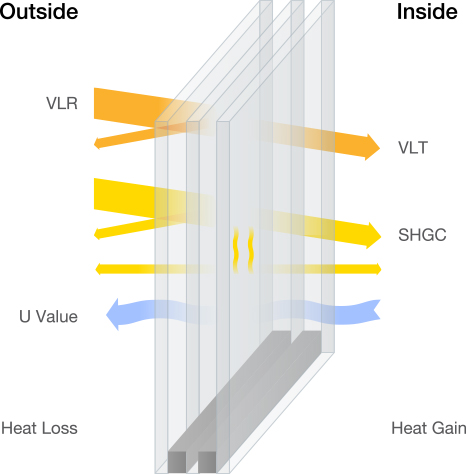

5. Ukushisa okushisayo

Ukusebenza kokuvikela ukushisa kuvame ukuvezwa inani lokumelana nokushisa kwewindi, futhi iyunithi ingu-m2•h•C/KJ. Kunamazinga amathathu ezabelo ezijwayelekile: R1=0.05, R2=0.06, R3=0.07. Kusetshenziswa amawindi okufakwa okushisayo okushisayo angu-6mm acwebezeliswe kabili, inani lokumelana ne-thermal convection lingafinyelela ku-0.05m2•h•C/KJ.

6. Ukuqina Kwamasondo Omhlahlandlela Inayiloni

Amafasitela ashelelayo kanye namamotho afakwayo asuswayo asetshenziselwa ukuhlola okuphindaphindayo kokuhamba ngezindlela zokuxhumanisa i-eccentric. I-diameter yesondo lenayiloni ingu-12-16mm, ukuhlolwa izikhathi ezingu-10,000; ububanzi besondo lenayiloni ngu-20-24mm, ukuhlolwa izikhathi ezingu-50,000; ububanzi besondo lenayiloni ngu-30-60mm.

7. Amandla okuvula nokuvala

Lapho ingilazi ifakiwe, amandla angaphandle adingekayo ukuvula noma ukuvala i-casement kufanele abe ngaphansi kwe-49N.

8. Ukuqina okuvulekile nokuvala

Ilokhi yokuvula nokuvala iqhutshwa yinjini ebhentshini lokuhlola, futhi ukuhlolwa okuqhubekayo kokuvula nokuvala kwenziwa ngesivinini sezikhathi ezingu-10 kuya kwezingu-30 ngomzuzu ngamunye. Uma ifinyelela izikhathi ezingu-30,000, akufanele kube nomonakalo ongajwayelekile.

Isikhathi sokuthumela: Jul-24-2023